Dr. Liquid's digital valve makes its debut! A high-profile moment for domestically produced hydraulic technology.

Release time:

2025-05-22

The grand opening of the China Iron and Steel Industry Association's Hydraulic Lubrication Professional Annual Meeting

Top Stage, Intelligent Manufacturing Speaks

As the "14th Five-Year Plan" draws to a close, the intelligent transformation of China's manufacturing industry is imminent, while traditional hydraulic technology has long been constrained by "stuck neck" problems—frequent valve sticking, high-temperature hazards, switching impact, energy consumption black hole…

The industry calls for a true technological revolution! China's Solution, Global Attention!

May 22, 2025, the China Iron and Steel Industry Association's "Hydraulic Lubrication Professional Annual Meeting" was grandly held, Liquid Doctor brand founder, product manager Xin Lieye took the stage to give a speech, and grandly launched Liquid Doctor digital hydraulic technology to global top experts, with 100% domestically produced and independently innovative hard-core strength, to challenge the industry's century-old pain points!

01

「Liquid Doctor Digital Valve」

Performance and price, double crushing

Yiayatong Hydraulics with "Hardcore Technology" directly addresses pain points, launching the Liquid Doctor digital valve series, four disruptive advantages reconstruct industry standards:

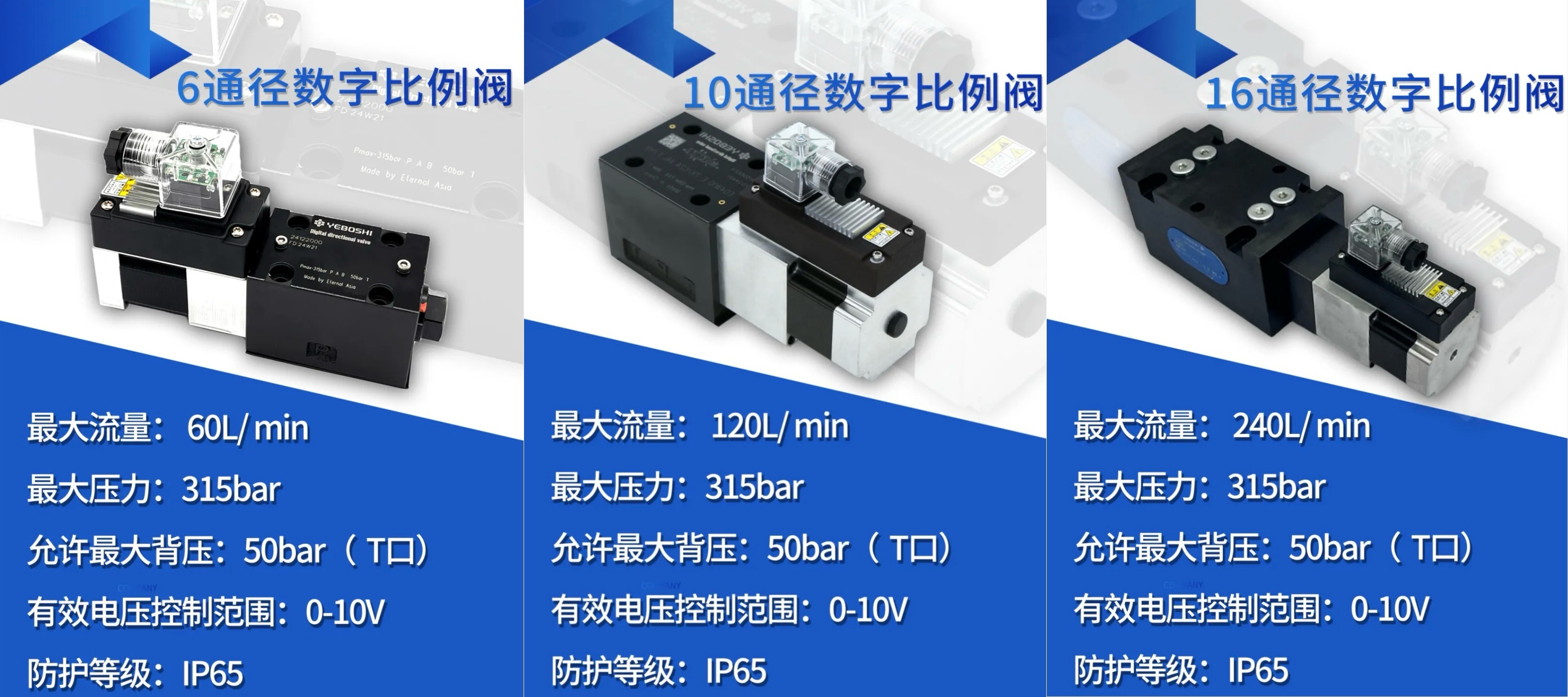

Digital proportional valve series products

>>Micron-level precision, redefining industrial control<<

Valve core repeat positioning accuracy 0.05mm ,cylinder accuracy 0.1mm ,comparable to laboratory standards, making equipment operation as precise as a "Swiss watch".

Applicable scenarios :High-end machine tools, precision metallurgy, engineering machinery, military industry, etc., bid farewell to the traditional hydraulic "crude era crude era ”

>>High temperature is not hot, stable as a rock<<

Unique temperature control technology, the reversing motor basically does not generate heat, the coil never burns, 80°C high temperature still runs "calmly" under.

Applicable scenarios :Iron and steel metallurgy, engineering machinery, military industry, metallurgy, water conservancy, agricultural machinery, high-end precision machine tools, etc., are not afraid of extreme environmental challenges!

>>Anti-stuck valve black technology, ending the "tractor-style" vibration<<

Ultra-large thrust design, oil blockage? Low temperature oil is thick? All invalid! Equipment operation is as quiet and stable as an "electric vehicle".

Applicable scenarios :Agricultural machinery, military equipment, even in harsh conditions can "smooth" operation!

>>Energy consumption killer, save a Wuling Hongguang MINI in a year<<

The comprehensive energy consumption is only 1/30 of ordinary electromagnetic valves, and the annual cost savings can buy a car! As low as 0.08A holding current, energy-saving and safe.

Applicable scenarios :Universal for all industries, cost reduction, profit surge

>>Intelligent maintenance, let the old masters "lie down and work"<<

5G remote monitoring, AI fault warning, predictive maintenance, One mobile phone controls the overall situation, and the risk of downtime is zero.

Applicable scenarios :Digital factory, unmanned production line, maintenance efficiency increased by 40%

Proven cases :From industry pain points to benchmark models After a leading steel plant replaced the Liquid Doctor digital valve, the noise of the hydraulic system changed from "tractor" to "electric vehicle", the annual number of shutdowns was zero, production efficiency increased by 40%, intelligent transformation was immediate, and maintenance costs were halved!

02

「Liquid Doctor's Mission」

More than just replacing imports, but defining the future!

Xin Lieye solemnly declared at the meeting: "The goal of Liquid Doctor is to make China's hydraulic technology a global standard!"

"Three-step" strategy >>

Yiayatong Hydraulics with "Three-step" strategy, leading the comprehensive evolution of hydraulic technology.

Component digitalization :Intelligent valve island + 5G interconnection, remote maintenance, fault warning one-click control.

System digitalization :18 months to achieve digital twin system integration, production line efficiency increased by 50%.

Platform ecologicalization :3 years to build the "HarmonyOS" in the hydraulic field, building a steel plant's full life cycle intelligent service chain.

Towards the future: Science and technology serve the country, industry wins together >>

Whether it is the "steel behemoth" of engineering machinery, the "field guardian" of agricultural machinery, or the "national treasure" of military equipment, the Liquid Doctor digital valve with performance crushes imported brands, and the price directly hits the pain points of domestic products, empowering the entire industry!

>>Intelligent driving profound changes<<

From "Breaking the deadlock of pain points" to Eco-leadership ” Yiayatong Hydraulics, driven by innovation, helps the steel industry move towards Digital Lubrication a new era.

In the future, the company will work with steel mills to achieve continuous technological iteration through the co-construction of laboratories and a tiered investment plan, allowing the "China Solution" to shine brightly on the global metallurgical stage!